Innovus

create & assign bump

power/ground bump

1 | create_bump –cell PAD90UBMBOP –loc_type cell_center –loc $x0 $y |

signal or power/ground bump

1 | set bump_name [create_bump –cell PAD150PITCH –loc $bump_x $bump_y –loc_type cell_center –return_bumps_name] |

Path Based Analysis

aocv : Re-timing the timing critical paths using the LOCV deratingfactors

path_slew_propagation : Re-timing the timing critical paths using the actual slews for thepath

aocv_path_slew_propagation : Combination of re-timing with aocv + path_slew_propagation

waveform_propagation : Re-timing with waveform effect taken into consideration during delayCal

Fix DRC Violation

1 | clearDrc |

check mode variants

1 | checkDesign |

Common Commands

Analysis Command

Clock Concurrent Optimization Technology (CCOpt)

Database Navigation

Data Exchange

Global Skew and Local Skew

Technology File

timeDesign vs. report_timing

Parasitic Extraction

Floorplan

/2022/02/07/Innovus/Tempus Nonfunctional ECO

Innovus ECO

block level create Power Ground Pin method

1 | editStretch x ... |

Add endcap and tapcell

First place place hard macro and add placement halo, then execute the following code to add endcap and tapcell.

1 | deleteFill -prefix ENDCAP |

First place place hard macro and add placement halo, then execute the following code to add endcap and tapcell.

1 | deleteFill -prefix ENDCAP |

In-design Sign-off Metal Fill Flow

Before inserting sign-off metal fill, stream out a GDSII stream file

of the current database. Specify the mapping file and units that match

with the rule deck you specify while inserting metal fill. If necessary,

include the detailed-cell (-merge option) Graphic Database

System (GDS).

PVS:

1 | streamOut -merge $GDSFile -mode ALL -units $GDSUNITS -mapFile $GDSMAP -outputMacros pvs.fill.gds |

Pegasus: 1

2streamOut -merge $GDSFile -mode ALL -units $GDSUNITS -mapFile $GDSMAP -outputMacros pegasus.fill.gds

run_pegasus_metal_fill -ruleFile $DUMMYRULE -defMapFile $DEFMAP -gdsFile pegasus.fill.gds -cell [dbgDesignName]

Just replace

run_pvs_metal_fillwithrun_pegasus_metal_fill

Note: Innovus metal fill (e.g.

addMetalFill, addViaFill, etc.) does not

support 20nm and below node design rules. We strongly recommend the

Pegasus/PVS metal fill solution for 20nm and below. If you have sign-off

metal fill rule deck for 28nm and above available, we recommend you to

move to Pegasus/PVS solution too.

trimMetalFillNearNetdoes not check DRC rules. It only removes the metal fill with specified spacingDo not perform ECO operations after dump in sign-off metal fill (by

run_pvs_metal_fillorrun_pegasus_metal_fill), especially, at 20nm and below nodes.If you perform an ECO action, the tool cannot get DRC clean because

trimMetalFilldoes not support 20nm and below node design rules.The sign-off metal fill typically does not cause DRC issues with regular wires.

The run_pvs_metal_fill command does the following:

- Runs PVS with the fill rules to create a GDSII output file.

- Converts the GDSII to a DEF format file based on the GDSII to DEF layermap provided.

- Loads the resulting DEF file into Innovus.

Pegasus is similar to PVS, shown as below,

The run_pegasus_metal_fill command does the

following:

- Runs Pegasus with the fill rules to create a GDSII output file.

- Converts the GDSII to a DEF format file based on the GDSII to DEF layermap provided.

- Loads the resulting DEF file into Innovus.

Reference:

Innovus User Guide, Product Version 21.12, Last Updated in November 2021

How does EDI System identify spare cells in a post-mask ECO flow?

How does EDI System identify spare cells in a post-mask ECO flow?

Spare cells should have a unique string in their instance name to

identify them. Then the command specifySpareGate or

ecoDesign -useSpareCells patternName is run to identify the

spare instances. For example, if all spare cells have _spare_ in their

name then they are identified using:

1 | specifySpareGate -inst *_spare_* |

OR

1 | ecoDesign -spareCells *_spare_* ... |

Note: if you are making manual ECO changes to a netlist and converting a spare cell to a logical instance, it's important to change the instance name. Otherwise, the instance may be identified as a spare cell if a future ECO is performed because it still has the spare cell instance name.

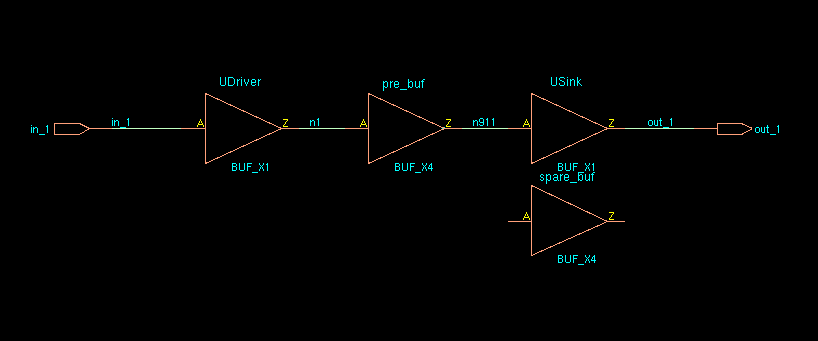

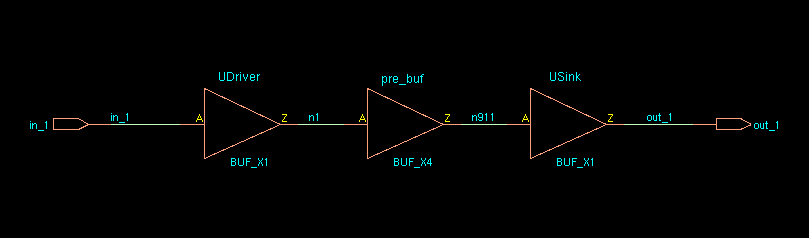

Example

The cell to be swapped is unplaced

pre_buf: unplaced

spare_buf: placed

innovus 49> dbGet top.insts.name

spare_buf pre_buf UDriver USink

innovus 50> dbGet top.insts.

0x7f7b03ef60e0 0x7f7b03ef6150 0x7f7b03ef6000 0x7f7b03ef6070

1 | specifySpareGate -inst spare_* |

innovus 55> dbGet top.insts.name

pre_buf UDriver USink

innovus 56> dbGet top.insts.

0x7f7b03ef6150 0x7f7b03ef6000 0x7f7b03ef6070

innovus 57> dbGet top.insts.Pstatus

placed fixed fixed

Note: sparecell's pointer and name is swapped with the unplaced cell.

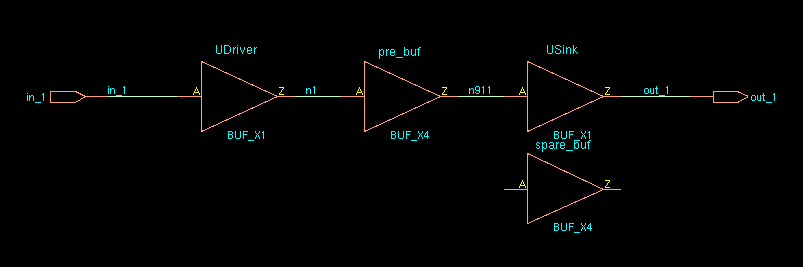

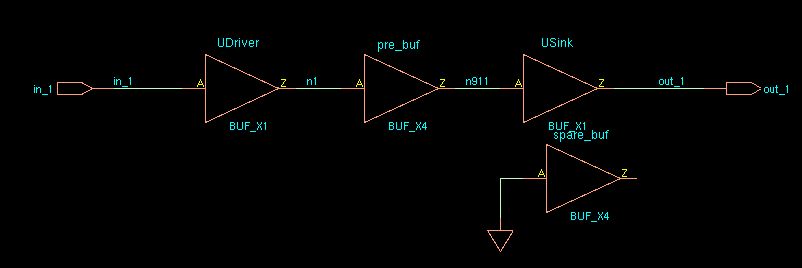

The cell to be swapped is placed

innovus 62> dbGet top.insts.name

spare_buf pre_buf UDriver USink

innovus 63> dbGet top.insts.

0x7f7b03ef60e0 0x7f7b03ef6150 0x7f7b03ef6000 0x7f7b03ef6070

innovus 64> dbGet top.insts.pStatus

placed placed fixed fixed

1 | innovus 66> specifySpareGate -inst spare_* |

innovus 68> dbGet top.insts.name

spare_buf pre_buf UDriver USink

innovus 69> dbGet top.insts.

0x7f7b03ef60e0 0x7f7b03ef6150 0x7f7b03ef6000 0x7f7b03ef6070

innovus 70> dbGet top.insts.pStatus

placed placed fixed fixed

Note: sparecell's pointer and name is swapped with the placed cell.

Error in "Innovus Text Command Reference 21.12"

ecoSwapSpareCell

If the cell to be swapped is unplaced, it is mapped to the spare

cell. *instName* is deleted, and its connection is

transferred to the spare cell. If the cell to be swapped is placed, it

is swapped with the spare cell and is renamed to

*instNameSuffix* if the -suffix option is

used. If a suffix is not specified, the *instName* cell is

renamed to *spareCellInstName*. The *instName*

cell's connections are transferred to *spareCellInstName*.

The input of *instName* is tielo, based on the

global connection definition.

reference

Answers to Top 10 Questions on Performing ECOs in EDI System

EE 582: Physical Design Automation of VLSI Circuits and Systems